Offering CNC Milling services to the Auckland area and beyond. The attention to detail and focus on quality at One Works means we have machined parts which are in use all around New Zealand and The world. Performance car parts, machine components, electrical enclosures, aerospace parts and more. From one off components and prototypes to mid volume production, and everything in between. All made to the same exacting standards.

Services

More than just machining

The Parts

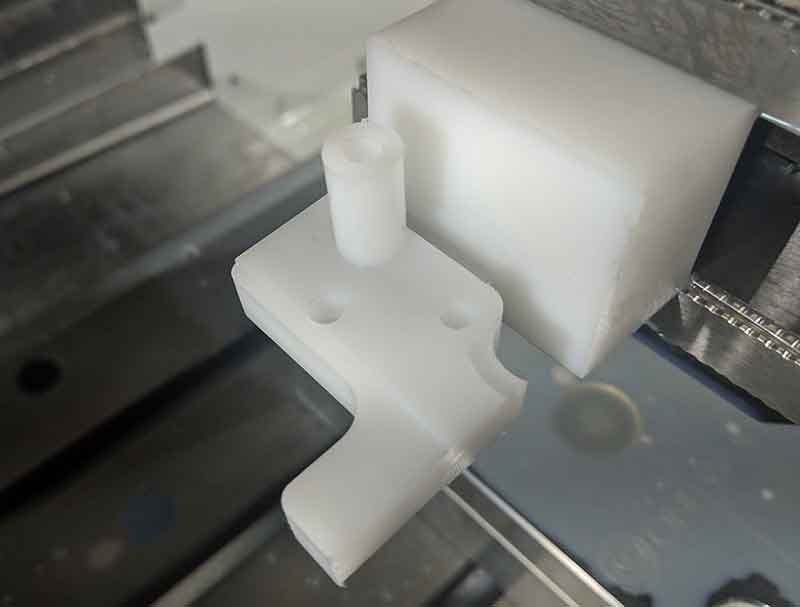

Utilising our Haas VF-3SS Vertical Machining Centre and HRT 210 Rotary Table as well as an assortment of some of the best work holding and tooling available. One Works produces high quality CNC Machined Parts. Our exceedingly high personal standards mean our customers are always thrilled with the parts they receive.

We have experience working with a variety of metals including various grades of Aluminium, steel, stainless steel, brass and zinc. As well as numerous types of plastics. If your material of choice is not listed, get in touch anyway, thanks to the support we receive from our world leading suppliers we’re able to quickly adapt to new materials.

The Rest

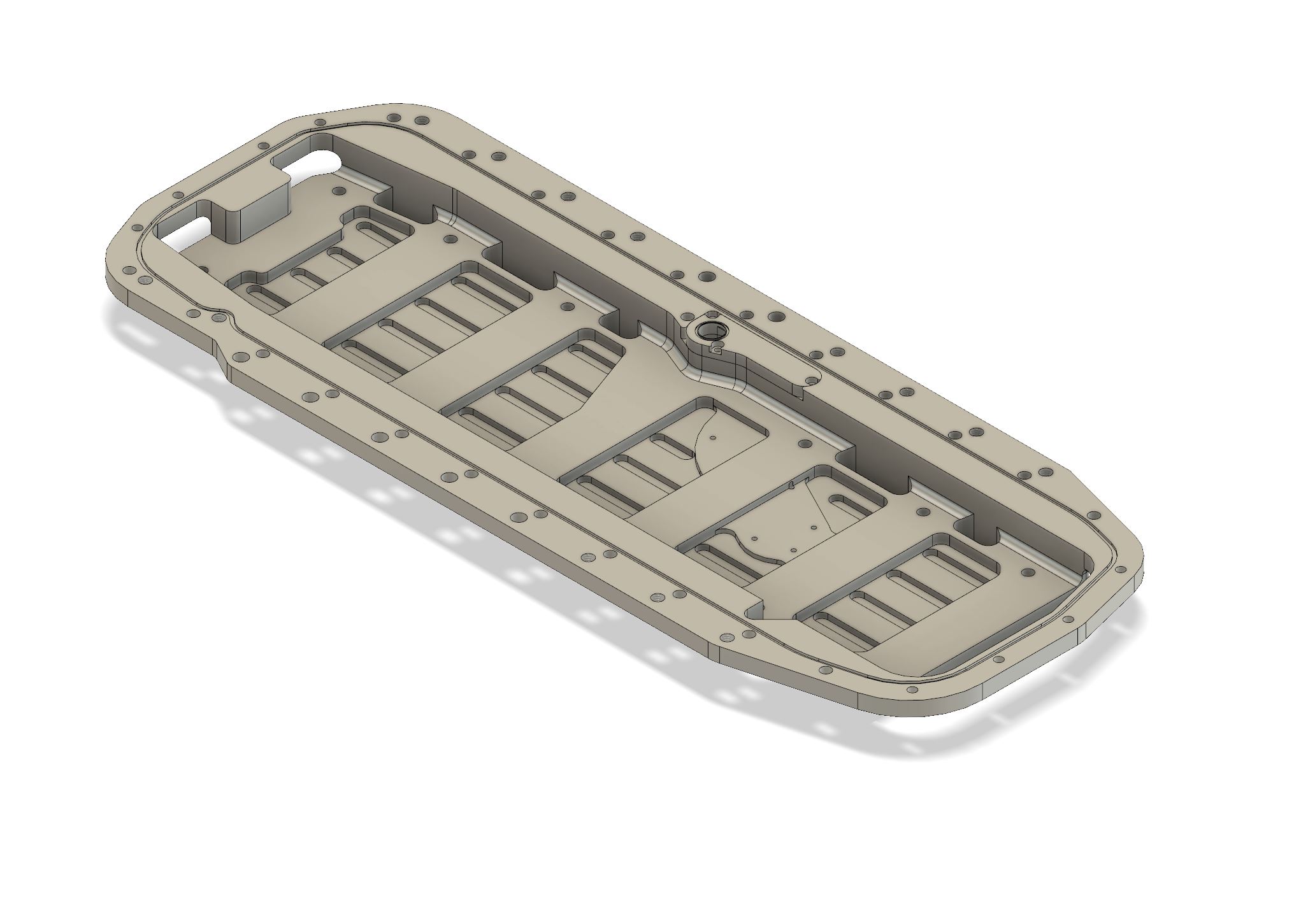

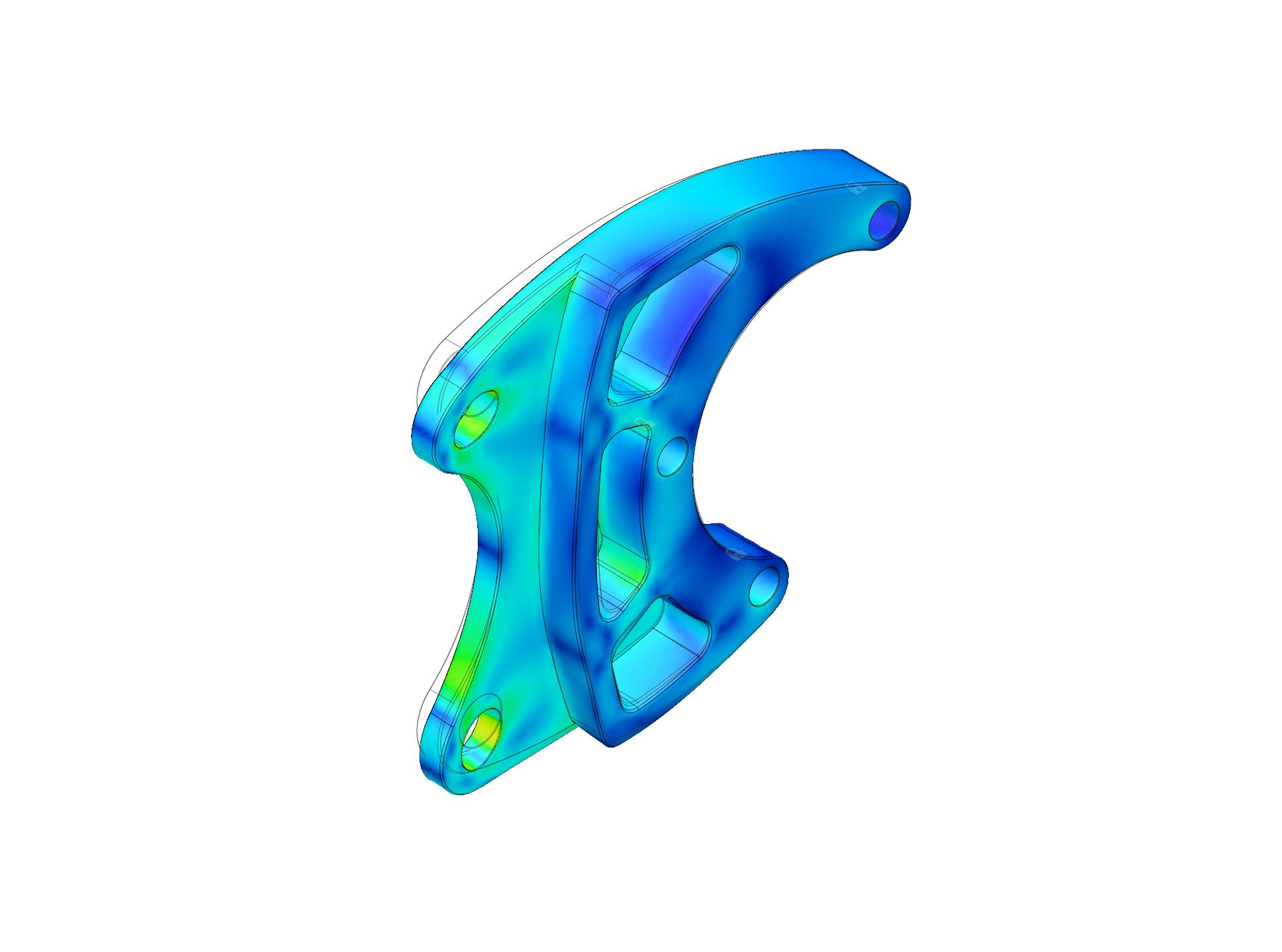

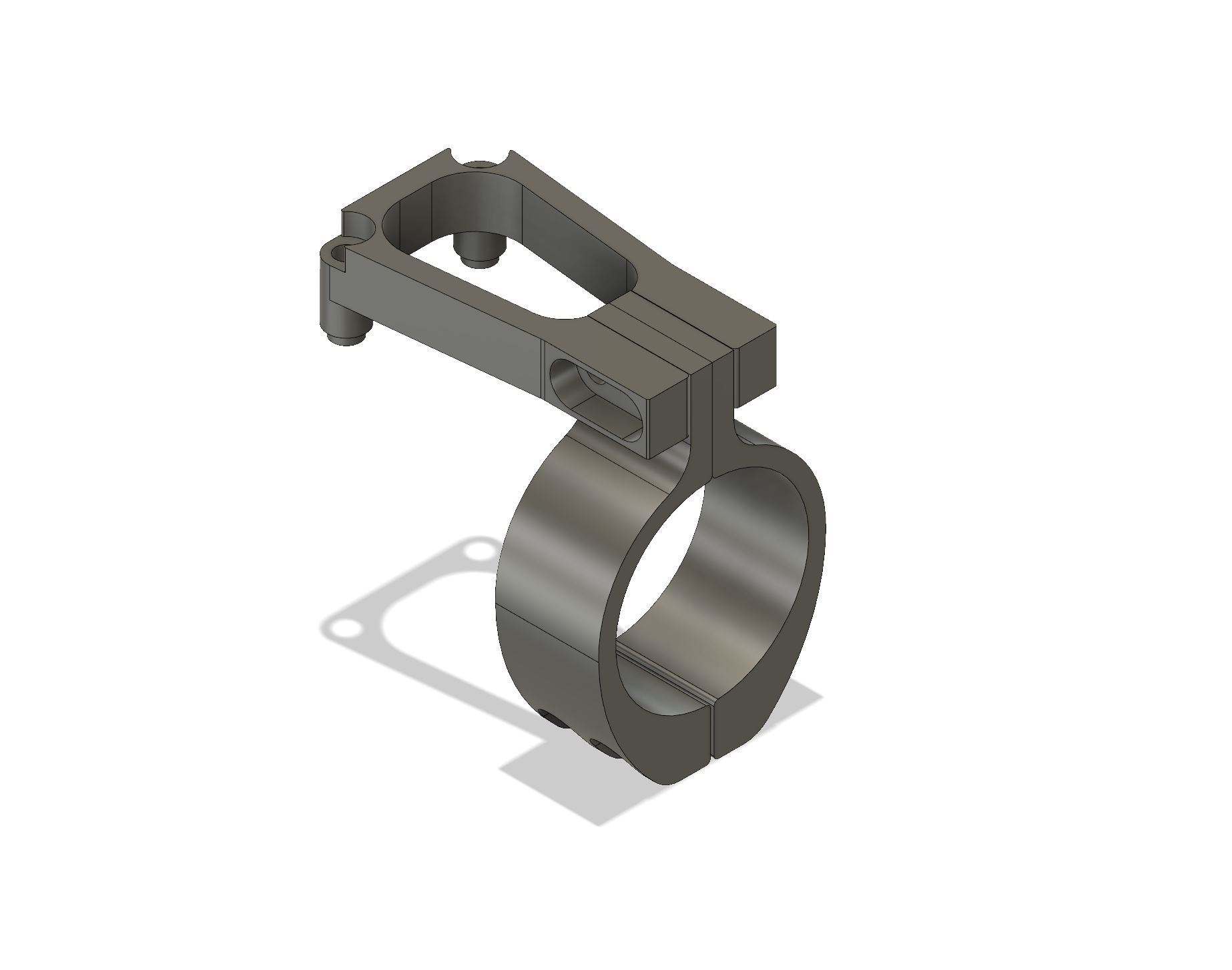

There is more to great parts than just the machining. To ensure our customers get the best possible product, we offer services beyond simply machining parts to the supplied design.

To compliment our machining service One Works offers CAD and design consulting services. From concept to completed product, we can help throughout the process. We often receive designs for low to mid volume production which aren’t optimised for machining. In such cases we will work with the customer to modify their design in ways that allow us to produce the part more efficiently and by extension at a lower cost to them.

Equipment

Quality parts require quality tools

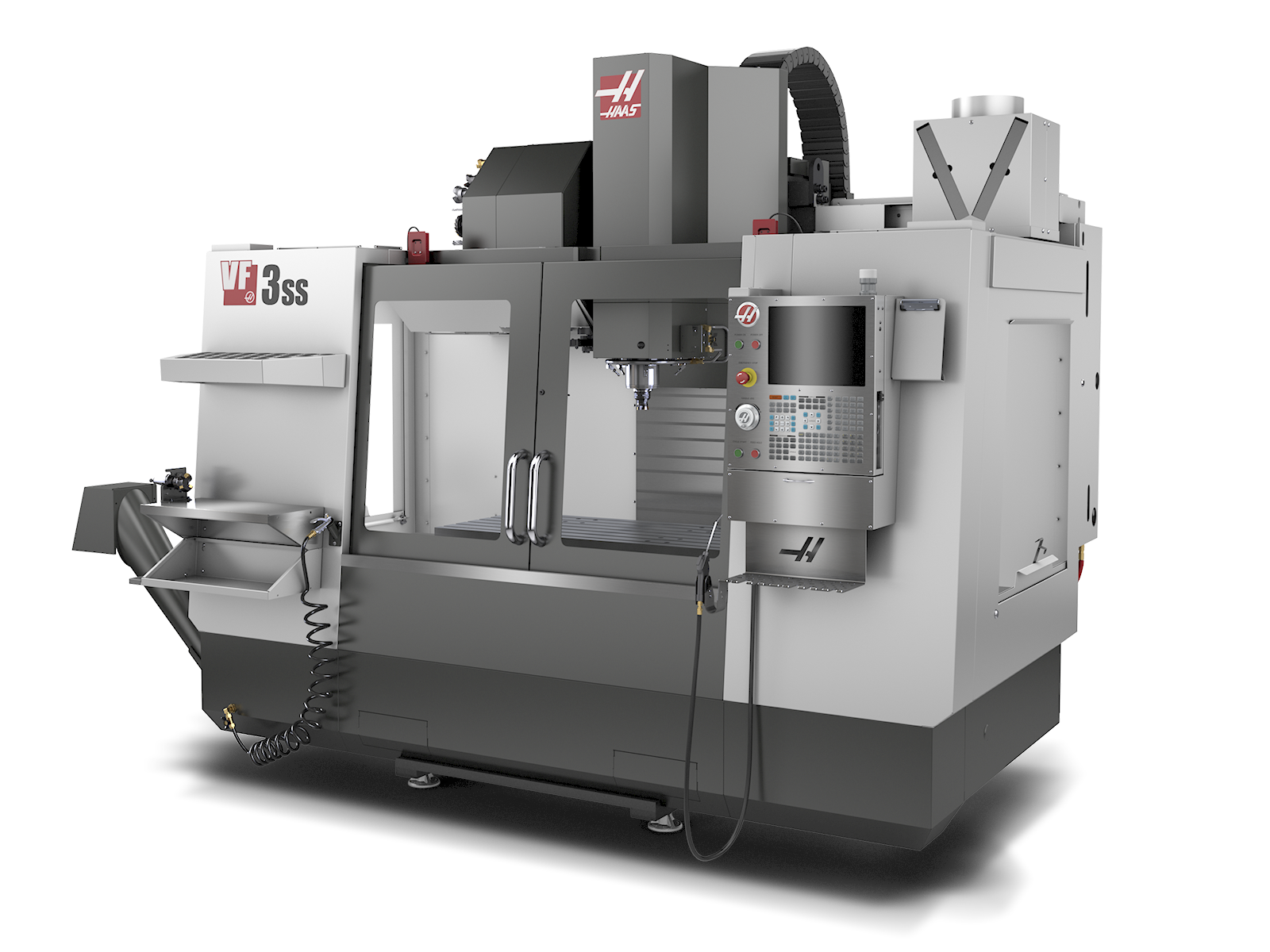

Haas VF-3SS Vertical Machining Centre

Specified by Haas Factory Outlet New Zealand and destined for their showroom, until we snapped it up before it made it there, our VF3-SS has all the best options to help us make the best parts.

Travels (XYZ) - 1016 x 508 x 635mm

15,000rpm Spindle - Fast material removal and high speed finishing

Wireless Intuitive Probing System - Supplied by Renishaw, a world leader in their field the probing system allows us to quickly setup part locations as well as performing mid cycle adjustments and inspection

Through Spindle Coolant (TSC) - Allows drilling at incredible speeds as well as increased material removal rates when milling

Through Tool Air Blast - Similar benefits to TSC for cutting conditions where coolant use is not suitable

Programmable Coolant Nozzle - Gets the coolant where it needs to be regardless of tool length

HRT210 Rotary Table

The addition of the HRT210 Rotary table along with 5th Axis work holding solutions has allowed us to greatly increase our capabilities. Reducing operations and setups allows us to produce parts more accurately and faster.

Partners

To make the best parts you need the best suppliers

contact us

Get in touch to discuss how we can help you